Behind the Scenes: The Art and Science of a Ball Holder

23/07/2025Ever wondered what goes into making something as seemingly simple as a ball holder? You might think it’s just a piece of plastic or metal that keeps your sports balls from rolling away, but there’s a lot more to it than meets the eye. Today, we’re taking you behind the scenes to explore the fascinating world of ball holders and see just how these everyday heroes come to life.

Imagine walking into a manufacturing plant where the air hums with the sound of machines. This is where the journey of a ball holder begins. The first step is design, where engineers and designers come together to brainstorm the perfect shape and functionality. It’s not just about holding a ball; it’s about making sure it does so safely and efficiently. They consider everything from the size of the balls it will hold to the materials that will endure wear and tear.

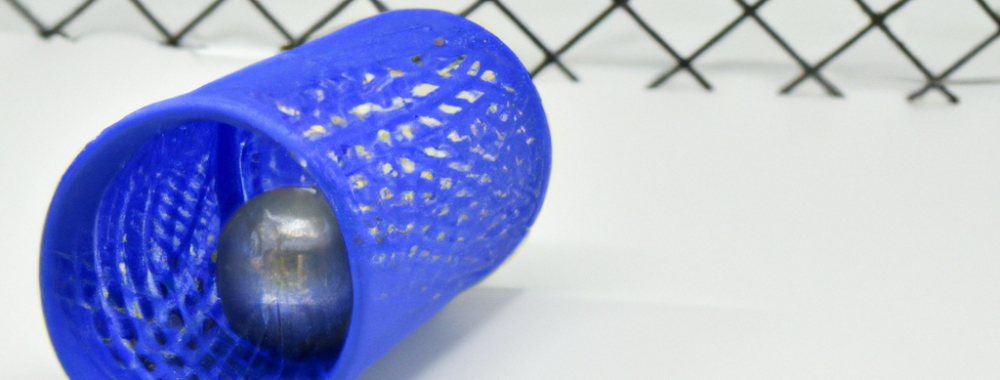

Once the design is finalized, it’s time to choose the materials. Many ball holders are made from durable plastics, such as polypropylene or polyethylene. These materials are lightweight yet sturdy, making them perfect for handling the weight and impact of balls. For more premium options, manufacturers might opt for metals like aluminum or stainless steel, providing an extra level of durability and a sleek look.

With materials selected, the manufacturing process kicks into high gear. Injection molding is a common method used for creating plastic ball holders. This process involves melting the plastic and injecting it into a mold. After cooling and solidifying, the ball holder takes its shape. For metal versions, techniques like die casting or CNC machining are used, which involve cutting and shaping the metal into its final form.

Quality control is a crucial stage in the production process. Each ball holder is meticulously inspected to ensure it meets the required standards. This step is vital because even a small defect can affect its performance. Workers check for things like cracks, irregular shapes, and proper dimensions. Only those that pass the rigorous checks make it to the packaging stage.

Packaging might not sound exciting, but it’s a key part of the process. A well-packaged ball holder not only protects the product during shipping but also enhances its appeal on the store shelf. Manufacturers often opt for eco-friendly packaging materials, keeping sustainability in mind. It’s a fine balance between protecting the product and being mindful of the environment.

After packaging, ball holders are shipped to distributors and retailers around the world. Whether they end up in sports stores, online marketplaces, or local shops, the journey from a concept in a designer’s mind to a useful product in your hands is complete. It’s a testament to the hard work and dedication of everyone involved in the process.

So, the next time you see a ball holder, remember the incredible journey it has been on. It’s not just a simple item; it’s a product of thoughtful design and meticulous manufacturing.

If you’re curious about more interesting behind-the-scenes stories or looking to find the perfect ball holder for your needs, check out our full range of products and articles. Head over to our shop to discover more.

Thanks for joining us on this fascinating journey. Whether you’re a sports enthusiast or just someone who appreciates the little things in life, there’s always more than meets the eye in the world of ball holders.